ESI ProCAST 2022新版发布!

ProCAST是一款积累了世界各地合作超过25年之久的主要工业伙伴、学术机构经验的先进工具。

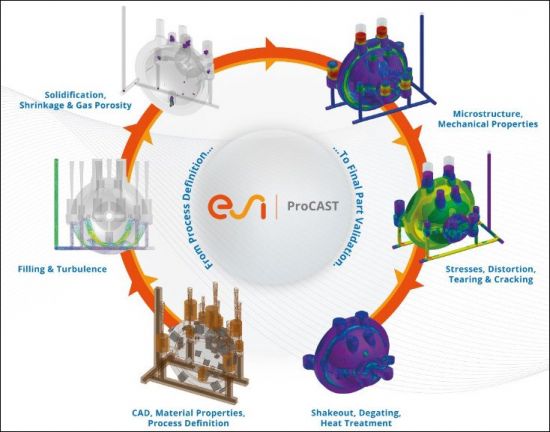

ProCAST 提供了一整套模块丰富的铸造工艺解决方案,全面满足您最具挑战性的工业需求。.软件基于有限元技术,非常适合预测变形及残余应力,还可以模拟更多的特殊工艺过程,如半固态、射砂制芯、离心铸造、消失模与连续铸造等。

ProCAST根据不用工业的需求。配置不用的模块,符合客户的不同需求。ProCAST基于强大的有限元理论,可准确地预测及模拟铸造缺陷,铸造过程中产生的变型,应力分布以及一些特殊的铸造工艺。如:半固态铸造、射砂制芯、离心铸造、消失模铸造、连铸等。

File Size: 4 GB

ESI Group – Leading Innovator in Virtual Prototyping Software and Services. Specialist in material physics established in more than 40 countries, ESI has developed a unique proficiency in helping industrial manufacturers replace physical prototypes by virtually replicating the fabrication, assembly and testing of products in different environments.

ESI has developed a set of casting simulation software applications for the foundry industry to improve casting yield and quality: QuikCAST — a fast and efficient solution for process evaluation — and ProCAST — an advanced tool which is the result of more than 25 years of collaboration with major industrial partners and academic institutions around the world. QuikCAST is sophisticated sand and die casting simulation software that focuses on the basics of any casting process: filling, casting solidification and porosity prediction.

ProCAST, based on Finite Element technology, in addition to the basics is able to predict deformations and residual stresses and can also address more specific processes like investment casting, semi-solid modeling, core blowing, centrifugal casting, lost foam, and the continuous casting process. Useful for all castable alloys, the metal casting simulation software helps to address defect detection, residual stresses, part distortion, microstructure and mechanical properties prediction. In 2006, ProCAST received the European Technology Leadership of the Year Award from Frost & Sullivan.

Virtual Environment

Enhancing the product design, improving its performance and faster go to market strategies are an absolute necessity for each and every product in today’s times. CFD, Multiphysics and Electromagnetics analysis in the virtual environment software helps many industries, research departments to bring a better product to the market by real life simulation of the design and testing it in all possible conditions before finalizing the prototype.

PAM-OPT is the solution to optimize and automate costly and time-consuming trial and error design and manufacturing.

When following the conventional approach, engineers iteratively use simulation or analysis software to check design performance. Once this is completed, they move on to analyze the results, make decisions, change the model and check again the new design until an optimal solution is reached.

PAM-OPT automates this loop, handling the decision-making concerning design changes and the job submission process on a network of computers.

PAM-OPT uses a series of algorithms which make decisions relative to design changes. PAM-OPT manages compute model parameterization, and launches pre-processing, solver and post-processing software modules.

By leveraging available computer and manpower resources, PAM-OPT helps manufacturers design better products with a reduced time-to-market.

Homepage

Password/解压密码www.tbtos.com

转载请注明:0daytown » ESI ProCAST 2021.5 Suite x64