利用Ansys CFD和Ansys ROCKY确保药品片剂包衣过程的产品质量

此次ESSS与Ansys联合推出的全新工作流程Ansys Rocky,是一种针对颗粒运动设计问题的可靠3D DEM解决方案。Ansys Rocky可以在多个GPU上,模拟大量的高精度、高保真的颗粒模型,并将分析速度提高20-90倍。在与Ansys® Fluent®和Ansys® Mechanical™无缝集成后, Ansys Rocky能够迅速的实现颗粒系统与流体、结构的全耦合仿真,模拟颗粒在诸如重力以及粘附力下的运动,确保新产品比以往更可靠。

百事公司研发总监Lei Zhao表示:“我们很高兴听到Ansys与ESSS合作的消息。众所周知,我们设计和制造的大多数产品都涉及颗粒系统,而且本质上是多组分和多物理的。百事公司的研发与工程团队借助Ansys Fluent开展计算流体动力学分析,采用Ansys Rocky开展颗粒动力学分析,以确保产品质量并优化制造工艺。最终缩短了产品研发周期,减少浪费并提高流程效率,并有助于满足对更健康、更环保产品日益增长的需求。”

使用Ansys ROCKY优化薯片包装

与传统的DEM软件不同,Ansys Rocky能够准确建模包含任意3D形状、2D壳和柔性纤维在内的颗粒形状,帮助工程师快速求解复杂几何设计方案的高难度设计问题。

ESSS首席执行官Clovis Maliska, Jr.指出:“从药片到薯片,能够为大量真实形状的颗粒建模,这使Rocky的适用范围从重型机械等传统领域,扩展至农业、电池设计和增材制造等新领域。此外,将Rocky集成到Ansys工作流程中,使DEM分析的功能扩展到设计中心之外,并让仿真进入制造、运营和生产领域,从而帮助企业优化大量的离散颗粒系统的生产、运输和包装材料处理。”

Ansys Rocky可提供独特的可用性、可移植性、求解器性能和多GPU加速,能以低成本计算颗粒传输。

Ansys高级副总裁Shane Emswiler称:“Ansys Rocky结合了定制与用户体验集成方面的最新技术成果,增强颗粒力学与流体力学、结构力学的耦合,帮助客户了解其产品在数千种现实工作场景下的性能。从建模复杂形状到柔性纤维,Ansys Rocky将其多GPU功能与Ansys旗舰版仿真相结合,让我们的客户能够迅速运行包含主要散体材料细节的大型、高逼真仿真。

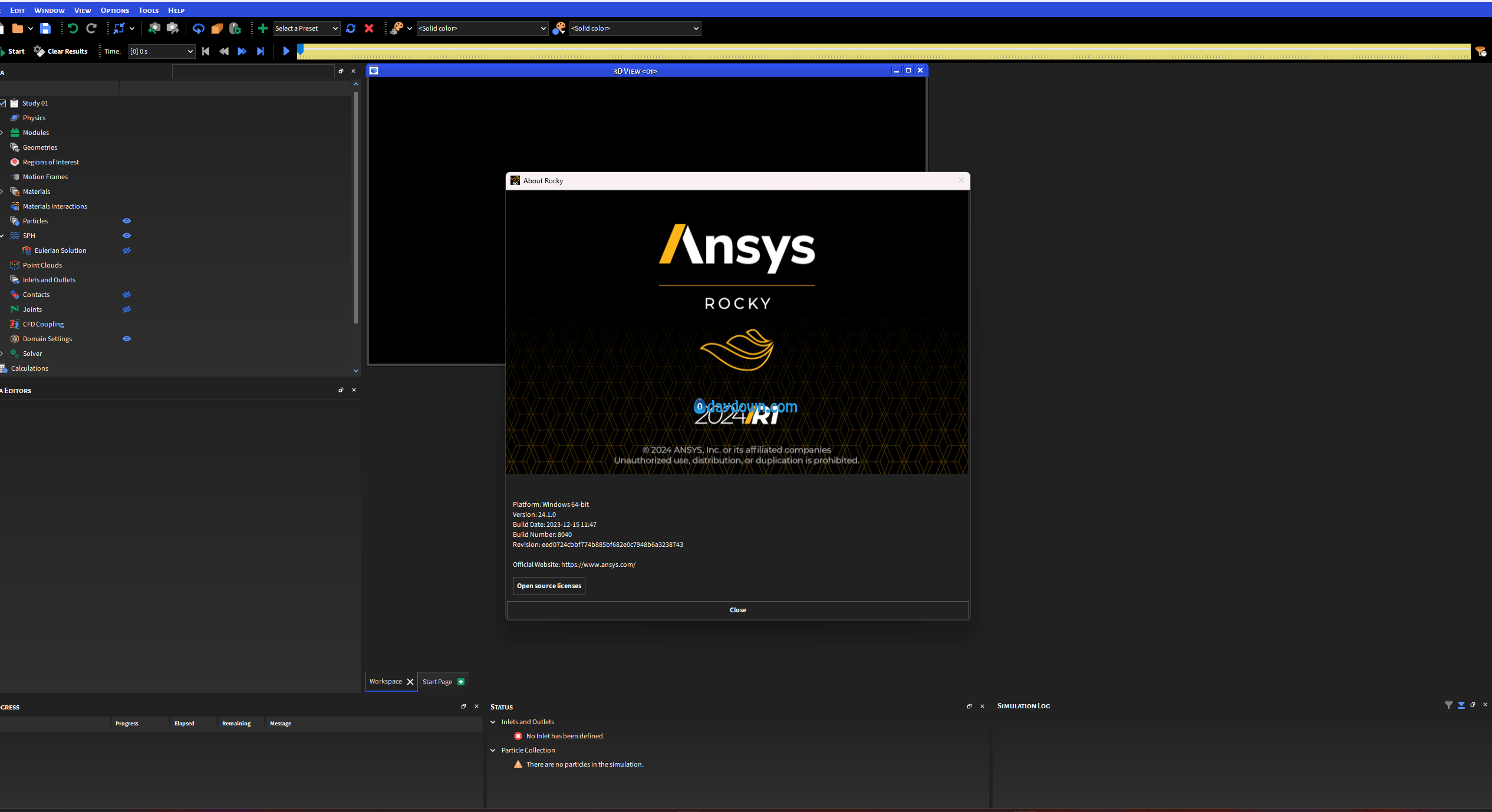

x64 | File Size: 1.32 GB

Description

Quickly and Accurately Simulate Particle Flows. Rocky is designed to solve engineering problems. Rocky is uniquely capable to models real particle shapes including any solids, 2D shells, and rigid and flexible fibers. The simulations are fast and accurate. With multi-graphics processing unit (GPU) solver technology, you can simulate the behavior of different shaped and sized particles in many industrial applications.

Accelerate your toughest particle simulations by using the most powerful DEM software in the market. Ansys Rocky contains industry leading features and capabilities to solve large, complex problems accurately and efficiently.

Multi-GPU Processing

Accurate Particle Physics

Automation and Customization

CFD Coupling

Surface Wear

3D Scan Import

Non-spherical Particle Shapes

Advanced Breakage Modeling

Multi Body Dynamics

FEA Coupling

2D Shells and Fibers

HPC

Compared to bench-top component-level testing, overall foulant simulation can produce savings of up to 10% of total development costs — along with reduced time to market, since results are available in a week, compared to months.

Built-in appliances fill today’s high-end kitchens, in which seamless integration with cabinetry can pose technical challenges related to airflow restriction in a machine’s compartment. This problem is exacerbated by dirt accumulation on the condenser (heat exchanger), which can affect appliance performance.

Experimental evaluation of dirt accumulation on condensers is time-consuming and expensive. Consequently, Sub-Zero is coupling Ansys Fluent computational fluid dynamics (CFD) and Ansys Rocky discrete element modeling (DEM) to quickly gain insight on the mechanisms behind dirt accumulation in an effort to design a more robust heat exchanger.

System Requirements

-64-bit OS: Currently Windows 10, Windows 11, Windows Server 2019, Windows Server 2022

-A graphics card that supports OpenGL;

-4 GB of free disk space;

-4 GB of RAM;

-Two-button mouse with center wheel;

-Screen resolution of 1280 x 1024.

Password/解压密码www.tbtos.com

Password/解压密码www.tbtos.com