Last updated 10/2021

MP4 | Video: h264, 1280×720 | Audio: AAC, 44.1 KHz

Language: English | Size: 14.01 GB | Duration: 24h 3m

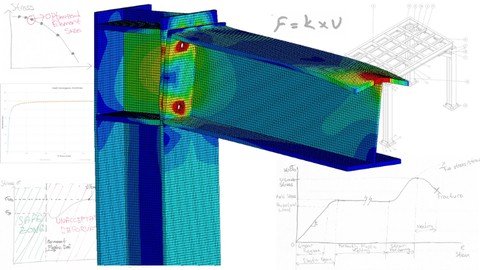

Linear Static Analysis with Finite Element Method

What you’ll learn

Fundamentals of Ansys Workbench

Defining Materials

Creating and Importing Geometry

Creating Parameters and Discussing the Effects of Parameters to Analysis.

Optimization Based On Parameters

Topology Optimization and Reducing Weight

Meshing in Details

Boundary Conditions (Loads and Supports)

Contact and Joint Types

Static Structural Section in Details

Structural Analysis

Hydrostatic Analysis

Connection Equipment Analysis

Static Linear Analysis

SpaceClaim

Simplifying the Geometry in SpaceClaim

Preparing the Geometry for Meshing and Contact Surfaces in SpaceClaim

Meshing in Advanced Level

Mesh Tips and Tricks in Advanced Level

Contacts in Advanced Level

Creating Submodel

Industrial Applications

Requirements

Having an Ansys Workbench

Being a student in Mechanical, Mechatronics, Manufacturing, or Civil Engineering.

Being curious about FEA or Ansys

Description

— Check My Website (importfea) —We are going to make a detailed examination of linear static analysis in the tutorial. After learning the necessary fundamentals, we will focus on the static structural section. In the static structural section, we’ll see all of the loads, supports, contacts, joints, and mesh types with applications.Versions 19.2, 19.3, and 2020R2 were used in the tutorial. For more detailed information and surprises, don’t forget to visit my Instagram page (@ansysegitim) :)We can gather the tutorial under 2 topics as introductory and advanced tutorials. We will be learning the topics below for the introductory course. Before reviewing these topics, I need to make it clear to you. First of all, let’s talk about what the tutorial does not include :)I did not include the non-linear analysis at this stage, since the topic is advanced. You are not going to see crashed trucks, plate-piercing bullets, flying aircraft, rockets, tanks or rifles, etc in the tutorial. All of these need separate courses. For this reason, learning them as a beginner in 10 minutes, 30 minutes, or 1-hour courses only teaches you to make colorful animations of that truck or plane ? The topics require mastery separately.Now, let’s examine what awaits us in the course. In the introduction part, my aim is to teach to use the Ansys. Each of the lessons is created with the aim of learning one specific topic within Ansys and is focused on that purpose. For example, if we are trying to learn the topic of boundary conditions, then we don’t struggle to get fine mesh quality or structures or we don’t need to prepare the model for meshing while we are learning the topic of contacts. You will get a better understanding of the applications after the theoretical lessons.In the tutorial, we will not only go to the analysis results with a few mouse clicks, we will reach the results by explaining which option we used and why we used it. Thus, after a while, you will be able to make many applications yourself.I have also covered in detail topology optimization (weight reduction) which is indispensable for design.I have also covered the topic of optimization. You will learn how to keep stresses below your desired value while improving the design by creating parameters.I have included in detail truss systems and structural analysis which are indispensable for static analysis.You will learn how to analyze fasteners especially bolted connections. I also added many more topics and applications related to static analysis to the first section of the tutorial In the second section, the advanced sections, we will be examining the following topics.Firstly, I wanted to make a reminder by going back to the fundamentals of engineering concepts from the very beginning. The fundamentals are topics that we must know and even develop. Under the title of fundamentals of engineering, you will see the topics of Stress, Strain, Young’s modulus, Poisson’s Ratio, and some important Material Properties. I explained all the commands separately that we will use frequently while preparing the geometries on SpaceClaim. We will discuss how to prepare a geometry/model, what should we pay attention to while preparing a geometry, what we should simplify, what should we keep in the geometry, and how to prepare geometry for meshing. I tried to explain the topic of advanced mesh in great detail from the scratch in advanced level mesh lessons. I started by teaching the mesh element types, the element orders, the effect of element types on the results, how to find the optimized element size, and how to make a mesh convergence study. I also gave you the tips that FEA Experts frequently use to obtain fine mesh structures. I suggest you definitely don’t miss this part. Under the title of advanced contact, we discussed the questions of what we should pay attention to while creating contact regions, which contact type is decent for which structures and what sub-settings come out while creating contact regions, how does it affect the results, when to use it and when to ignore it.We examined the topic of submodeling which is indispensable for an analysis. You will learn how to create a submodel and what you should pay attention to while creating them. And the final and great topic is the Industrial Applications. You should definitely not miss it. You will see some real-world engineering problems that I have run the analysis as a structural analysis engineer. We examined these projects in detail and examined how we solved them from the very beginning to the very end of the analysis (The dimensions of the projects were changed and some changes were made to ensure that they were not exactly the same but you will get the main idea).Goodbye for now…

Overview

Section 1: Finite Element Method

Lecture 1 Finite Element Method

Section 2: Ansys Workbench

Lecture 2 Interface of the Workbench

Lecture 3 Defining Materials

Lecture 4 Creating and Imporing Geometry.

Lecture 5 Basic Example

Section 3: Topology Optimization and Design Parameters

Lecture 6 Paramter and Optimization

Lecture 7 Example for Parameters in 2D Geometry

Lecture 8 Topology Optimization – 1

Lecture 9 Topology Optimization – 2

Lecture 10 Symmetry Feature – 1

Lecture 11 Symmetry Feature – 2

Lecture 12 2D Wrench

Section 4: Interface of the Mechanical

Lecture 13 Interface of the Mechanical

Lecture 14 Pre-Processing Steps

Lecture 15 Object Generator

Lecture 16 Frame Example – Share Topology Feature

Lecture 17 Truss Systems Example

Lecture 18 Vase Example – Hydrostatic Pressure

Section 5: Introduction to Mesh

Lecture 19 Global Mesh

Lecture 20 Local Mesh – 1

Lecture 21 Local Mesh – 2

Lecture 22 Torsion Example

Lecture 23 Bike Crank Example

Lecture 24 Creating Sensitive Mesh Structures

Section 6: Boundary Conditions

Lecture 25 Support Types

Lecture 26 Load Types

Lecture 27 Structural Analysis Example

Lecture 28 Garden Fountains Example – Hydrostatic Pressure

Section 7: Contact Types

Lecture 29 Contact Types

Lecture 30 Stand Example

Lecture 31 Plate-Bar Example

Lecture 32 Clevis Example

Section 8: Joint Types

Lecture 33 Joint Types

Lecture 34 Pendulum Example

Lecture 35 Piston Example

Section 9: Examples

Lecture 36 Practice 1 – Bended Plate

Lecture 37 Practice 2 – Bearing Load

Lecture 38 Practice 3 – Bridge

Lecture 39 Practice 4 – Connection Bracket

Lecture 40 Practice 5 – Supporting Bracket

Lecture 41 Practice 6 – Rotor

Lecture 42 Practice 7 – Arm Shaft

Lecture 43 Practice 8 – Flange Connection

Lecture 44 Practice 9 – Connection Plates

Lecture 45 Practice 10 – Bolt Pretension

Lecture 46 Practice 11 – F1 Motors Nozzle

Section 10: Advanced 1 – Fundamentals of Engineering

Lecture 47 Stress and Strain

Lecture 48 Young’s Modulus and Poisson’s Ratio

Lecture 49 Material Properties

Section 11: Advanced 2 – SpaceClaim and Preparing/Simplifying Geometry

Lecture 50 SpaceClaim

Lecture 51 Preparing and Simplifying Geometry

Section 12: Advanced 3 – Mesh in Details

Lecture 52 Element Types and Orders

Lecture 53 Differences in Dimensions (3D, 2D, and 1D)

Lecture 54 Optimized Element Number

Lecture 55 Comparison of TET and HEX Elements

Lecture 56 Mesh Convergence

Lecture 57 Mesh Tips – 1

Lecture 58 Mesh Tips – 2

Lecture 59 Mesh Tips – 3

Lecture 60 Mesh Tips – 4

Lecture 61 Mesh Tips – 5

Section 13: Advanced 4 – Contact Regions

Lecture 62 Advanced Contact Regions

Section 14: Advanced 5 – Submodelling

Lecture 63 Submodeling

Section 15: Advanced – 6 Industrial Applications 1 – Beam-Column Connections

Lecture 64 Model Preparation

Lecture 65 Boundary Conditions

Lecture 66 Contact

Lecture 67 Mesh

Lecture 68 Post Processing

Lecture 69 Creating Submodel

Lecture 70 Preparing Submodel

Lecture 71 Submodel – Boundary Conditions

Lecture 72 Submodel – Mesh 1

Lecture 73 Submodel – Mesh 2

Lecture 74 Submodel – Mesh 3

Lecture 75 Submodel – Mesh 4

Lecture 76 Submodel – Contact

Lecture 77 Submodel – Post Processing

Section 16: Advanced 7 – Industrial Applications 2 – Industrial Stair

Lecture 78 Model Preparation

Lecture 79 Material Properties

Lecture 80 Boundary Conditions

Lecture 81 Mesh – 1

Lecture 82 Mesh – 2

Lecture 83 Mesh – 3

Lecture 84 Contact

Lecture 85 Contact Status Checking with Modal Analysis

Lecture 86 Post Processing

Section 17: Bonus Content – What’s Next?

Lecture 87 Buckling in Ansys

Studens in Engineering,Everyone who wants to learn FEA or Ansys

Password/解压密码www.tbtos.com

转载请注明:0daytown » Ansys – Finite Element Analysis And Industrial Applications