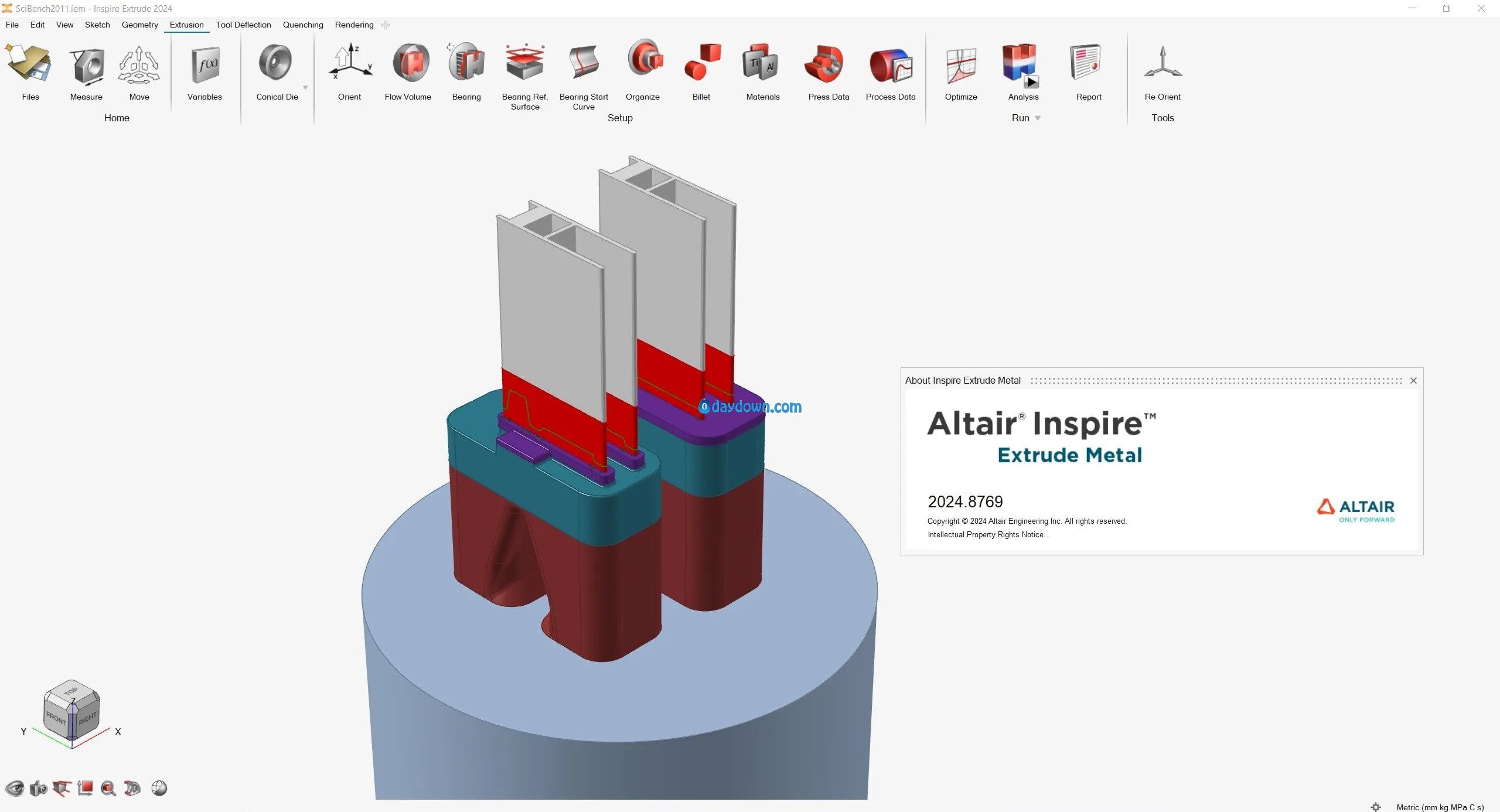

专为进行高效金属挤压设计

所有挤压公司都希望消除成本高昂的原型设计,缩短重新设计周期。现在,各种规模的企业组织均可获得高等物理特性仿真技术。Inspire Extrude Metal 易于掌握,让所有工程师或设计师都能通过仿真,更好地了解任何特定金属合金的型材特性和工艺变量如何相互作用。该工具可降低产品开发成本,改善挤压质量并提高产量和客户满意度,进而帮助您的团队提高生产力。

在制造模具之前检测潜在的缺陷,这样有助于做出更好的设计决策。借助 Inspire Extrude Metal,即使是极其复杂的型材,也能验证其生产可行性。利用几何创建和简化工具,可在该工具内部快速对 CAD 进行简化和修改,确保在开发早期阶段纠正潜在的型材变形、变形造成的损坏、后端缺陷、横向焊合缺陷、缝焊不良、晶粒尺寸粗大、过热、型材质量以及表面质量不良等问题。

用户可以通过在虚拟挤压机上探索工艺改进方法来降低报废率。通过仿真,您可以查看生产线内部的情况并微调过程变量,减少可见和不可见的缺陷。Inspire Extrude Metal 具有如下功能:快速研究挤出模具的性能,了解型材变形情况,实现零部件温度可视化,对工具组件的弹性和弹塑性特性进行建模,通过自动承压面优化校正模具,预测淬火速率。

Altair has released Inspire Extrude 2024.0 is an easy-to-use tool for simulating metal extrusion, polymer extrusion, and friction stir welding processes to detect potential defects early in the product development phase and improve the process efficiency.

New Features and Enhancements 2024

The Inspire Extrude 2024 release includes the following new features and enhancements.

General

Additional Parameters

Users can set the additional parameters in a file named “AdditionalParameters.txt”, and it will automatically be copied to the run folder. This feature will utilize new features in solvers that are not yet supported in the interface.

Metal Extrusion

Profile Die Creation

A new feature to create a profile die with a pocket is implemented. It will support multi-hole die. The presence of a pocket is optional. This is part of the die creation initiative. With this new implementation, we have three features for die creation. (INSTRUDE-3512)

Tool Deflection

Quick Analysis using SimSolid

Real-time elastic analysis with assumed loads using SimSolid is implemented in this release. This will help the users evaluate the performance of the tool stack and help improve the design before embarking on a detailed stress analysis based on computed loads with OptiStruct. (INSTRUDE-3444)

Polymer Extrusion

Roller BC

The interface now supports the specification of the roller boundary condition. Users can specify the RPM and the temperature of the roller. The interface will automatically determine the roller center and the diameter. Automatic meshing does not support models with rollers and the user will have to use the “start with existing mesh” option. This feature will help set up tire extrusion models that use rollers.

Improvement in Automatic Part Renaming Inconsistency in the automatic renaming of the created/organized components is removed. Now they will be named a Plate<Number>_L<Polymer Layer Number>. For example, parts from die plate 3, will be named Plate3_L1, Plate3_L2, etc. (INSTRUDE-3514)

Altair Inspire Extrude is a simulation environment designed to help extrusion companies meet the ever increasing demands to produce complex profiles with tight tolerances, quality surface finishes, and high strength properties at reduced cost. Altair Inspire Extrude is a simulation solution for both metal and polymer extrusion. It helps achieve productivity gains by reducing product development costs and improve extrusion quality, increasing production yield. Altair Inspire Extrude is a virtual press where users can visualize material flow and temperature inside a die during extrusion and make necessary changes to ensure balanced flow, while identifying and eliminating product defects.

Altair is a global technology company that provides software and cloud solutions in the areas of product development, high performance computing (HPC) and data analytics. Altair enables organizations across broad industry segments to compete more effectively in a connected world while creating a more sustainable future.

Owner: Altair

Product Name: Inspire Extrude

Version: 2024.0

Supported Architectures: x64

Website Home Page : http://www.altair.com

Languages Supported: english

System Requirements: Windows *

Size: 4.6 Gb

Password/解压密码www.tbtos.com