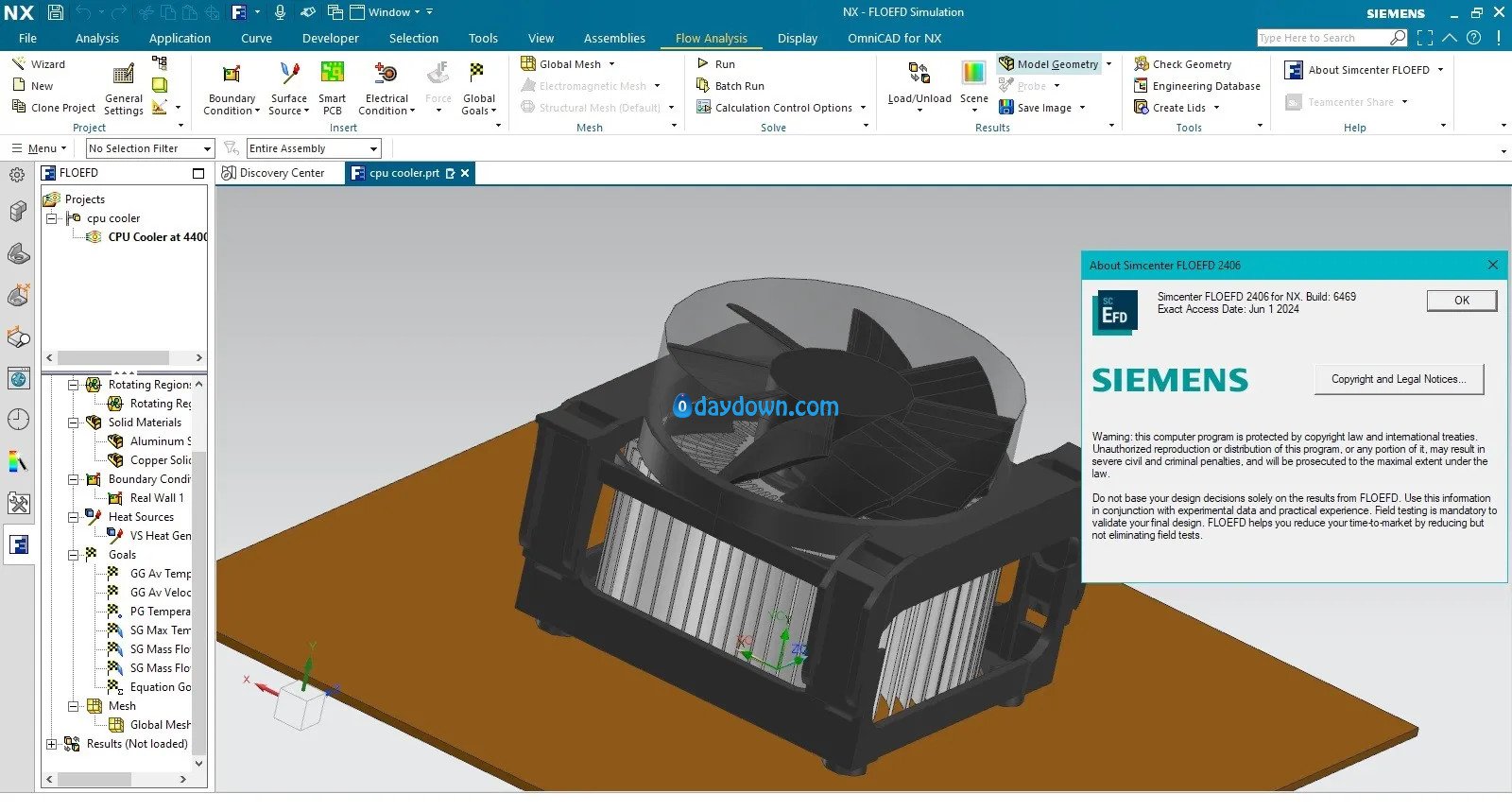

Simcenter FLOEFD 是一款完全嵌入 CAD 的 CFD 软件,具有多物理场功能,适用于设计师和分析师。该软件通过在开发设计早期进行流体流动仿真和热分析,并使用原生 CAD 几何体,可将开发时间比普通 CFD 方法缩短多达 65-75%。

前期 CFD 仿真可缩短开发周期

Simcenter FLOEFD 使设计工程师能够在设计流程的前期进行仿真,此时识别和修复问题或探索改进更具成本效益。它集成在 CAD 中,可将生产率提高 2 到 40 倍。

运用对设计师友好的直观 CFD 界面

通过 Simcenter FLOEFD 嵌入的 CAD 界面、引导式仿真设置和执行、智能自动化技术以及直观的结果查看方式,方便设计工程师进行仿真。他们能够尽早探索设计性能,无需克服传统障碍即可做出明智决策。

直接对原生 CAD 几何体执行 CFD,并消除 CFD 开销

消除工具之间几何体转换的延迟,并克服为 CFD 分析准备 CAD 几何体的复杂性。Simcenter FLOEFD 直接使用原生几何体:因此,当您探索性能或评估对模型做出的更改时,CAD 模型会同步更改。

它在强大的自动网格划分和独特的 SmartCell 技术方面具有明显优势,可以处理任何质量的 CAD 几何体。这些优势有助于处理装配体中的窄小间隙和表面不一致性,而传统的 CFD 工具通常会导致修复延迟过长。此外还有智能自动化预处理,如 CAD 几何体的自动密封和渗漏识别。

使用仿真驱动型设计 – 探索、比较和优化

利用参数化研究和设计探索功能,在可用时间内评估更多设计方案。评估“假设”场景,确保产品在不同条件下的性能和可靠性。

使用该软件,只需点击几下,即可轻松通过 CFD 可视化结果图、绘图和表格结果对设计进行并排比较,并生成报告。通过仿真优化设计后,您可以直接将 CAD 模型传递给其他工程设计部门。

File size: 1.2 GB

FloEFD for Siemens Simcenter3D Applications for fluid and gas flow and heat transfer simulation in the Siemens Simcenter3D environment. FloEFD is fully integrated into the iemens Simcenter3D environment and uses computational fluid dynamics (CFD) based solvers.

Main advantages

Working directly with the model in the Siemens Simcenter3D environment

There is no need to convert geometry to another format, which often leads to a loss of quality.The task of calculating fluid dynamics and heat transfer at any time is fully synchronized with the model

Minimization of efforts, and as a consequence, errors in the synchronization process of the set fluid dynamics problem and the model

Automatic detection of changes in the model.

There is no need for “manual” construction of the geometry describing the area occupied by the liquid / gas

Automatic detection of the area occupied by liquid / gas.

Uses the same graphical controls as other PTC Creo Parametric modules

Very easy to learn

Easy to use

Uses the PTC Creo Parametric model tree.

Intuitive and fully interactive

Use when creating a project / processing results of model elements selected in the graphics window / model tree

Visualization of calculation results in the form of static and animated images directly in the graphics window

Support for exporting results to MS Excel, Word. The ability to play and record animations.

Support for multi-configuration of the model.

For an efficient multi-parameter study, there are implemented – the ability to clone projects, automatic start of a series of calculations.

Automated to reduce the number of cases when it is necessary to involve specialists in the field of fluid dynamics and heat transfer to analyze the formulation and calculation results

Reliable and fully automatic generator of computational grids

A unique model of turbulence and boundary layer is used.

Automatic control of the convergence of the solution.

Reliable and accurate numerical methods and physical models

Large set of physical models

Exact solution

Ability to calculate very complex structures and physical phenomena.

Computational Fluid Dynamics (CFD) and allows you to analyze a wide range of complex problems, including

• Analysis of hydro-aerodynamics and heat transfer of two – and three-dimensional models

• Analysis of external and internal flow flows

• Analysis of steady and unsteady flow

• Incompressible liquid and compressible gas flow , including including combustible mixture, at subsonic,

transonic, supersonic and hypersonic flow regimes

• Condensation of water vapor

• Calculation of the relative humidity of air in gas flows

• Flow in non-Newtonian fluids (only laminar flow regime)

• Flow in a compressible fluid (fluid density depends on pressure)

• Flows in real gases

• Laminar analysis , turbulent and unsteady flows

• Analysis of vortex flows and fans

• Analysis of flows with solid inclusions

• Analysis of heat transfer inside and between liquids and solids

• Analysis of heat transfer inside solids in the absence of a washing flow

• Calculation of thermal contact resistance

• Calculation of electrical contact resistance

• Thermoelectric coolers

• Heat transfer by radiation

• Joule heating

• Flows with gravitational effects (also known as the buoyancy effect)

• Porous media

• Heat pipes

• Heat transfer in printed circuit boards

• Heat transfer in perforated plates

• Aerosol flow

• Taking into account the roughness of bodies during

tangential flow wall movements (stirring and rotating)

• Flow in rotating devices

• Cavitation in liquid flows

• Combustion in gas mixtures

Password/解压密码www.tbtos.com

转载请注明:0daytown » Siemens Simcenter FloEFD 2406.0.0 v6469 for Siemens NX / Simcenter 3D