AutoForm TubeXpert是一款操作方便且高度直观的软件解决方案,用于快速设计工具和模拟管材折弯、成形和液压成形过程。该软件能够满足用户有关零件复杂性、零件质量和高级材料(如高强钢和铝)的日益增长的需求,以及日益复杂和多样化的成形工艺。

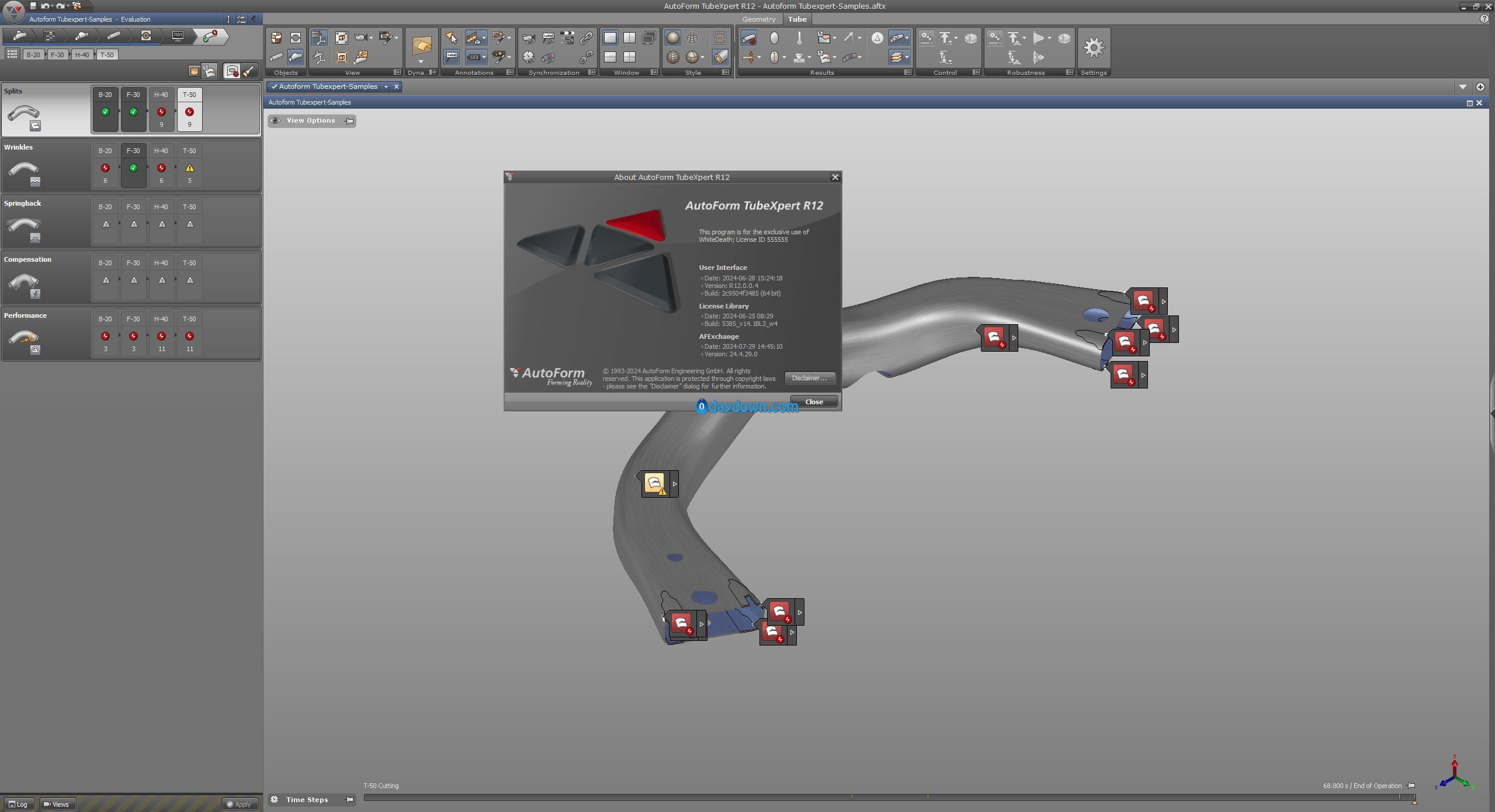

通过AutoForm TubeXpert,用户可以对管材的成形过程进行全面的虚拟调试分析,包括从折弯和预成形到液压成形、退火和校正、切割和管端成形的所有工艺步骤。冷管和热管成形都可以解决。此外,该软件帮助用户能够在任何成形工艺步骤后执行精确的回弹模拟,并自动对模具几何图形和工艺参数进行必要的调整,以补偿回弹的影响。AutoForm TubeXpert中AutoForm-Sigma技术的全面集成帮助用户能够作为零件设计师、工艺工程师或模具制造商系统地改进模具设计和工艺布局,并评估制造工艺的稳健性。

优点

- 管材的快速工具体和工艺设计

- 验证质量和成本优化多种备选方案

- 深入了解管材整个成形过程

- 缩短开发时间,降低模具、材料和生产成本

- 提高工艺可靠性,实现稳健制造

主要特点

- 快速创建所有必要的模具设计和完整的冷热管成形过程的无缝工艺模拟

- 可靠、自动识别成形问题,如开裂、起皱或校准不足

- 任何成形工序后的回弹模拟和回弹补偿的自动模面修改

- 系统性工艺优化和工艺稳健性评估,以实现可靠的制造工艺

- 执行公司标准和自动生成报告

x64 | File Size: 671 MB

Description

AutoForm TubeXpert is an easy-to-use and highly intuitive software solution for rapid tool design and simulation of tube bending, forming, and hydroforming processes. The software enables you to meet the increasing demands regarding part complexity, part quality and advanced materials, such as advanced high-strength steels and aluminum, as well as the increasing complexity and variety of forming processes.

With AutoForm TubeXpert, you can carry out comprehensive virtual tryout analyses of the forming process of tubular parts including all process steps from bending and preforming to hydroforming, annealing and calibration, cutting and tube end forming. Both cold and hot tube forming can be addressed. In addition, the software enables you to perform accurate springback simulation after any of the forming process steps and automatically make the necessary adjustments to the tool geometry and process parameters in order to compensate the effects of springback. The full integration of AutoForm-Sigma technology in AutoForm TubeXpert enables you as a part designer, process engineer, or tool and die maker to systematically improve tool designs and process layouts as well as evaluate the robustness of the manufacturing process.

Benefits

-Rapid tool and process design for tubular parts

-Verification of multiple alternative concepts for quality and cost improvements

-In-depth understanding of entire forming process for tubular parts

-Shorter development time and reduced tooling, material, and production costs

-Improved process reliability for robust manufacturing

Key Features

-Rapid creation of all necessary tool designs and seamless process simulation of complete cold and hot tube forming processes

-Reliable and automatic identification of forming issues, such as splits, wrinkles or insufficient calibration

-Springback simulation after any forming operation and automatic tool modification for springback compensation

-Systematic process improvement and evaluation of process robustness for a reliable manufacturing process

-Implementation of company standards and automatic report generation

System Requirements

OS:Windows 10 (Pro, Enterprise)/Windows 11 (Pro, Pro for Workstations, Enterprise)/Windows Server 2016 or newer

Supported on x86-64 microprocessor architecture only.

AutoForm setup needs .NET 3.5 Client Profile.

转载请注明:0daytown » AutoForm TubeXpert R12 x64

Password/解压密码www.tbtos.com

Password/解压密码www.tbtos.com