InnovMetric发布新版PolyWorks Metrology 2022!

现在,PolyWorks|Inspector™使您可以同时为多个测量工件修改和添加数据对齐、测量对象以及检测报告,这样您就能够:

准备稳健的能处理所有工件的检测项目

- 构建初始项目并开始测量工件

- 发现存在问题的工件时,微调抽取和拟合参数

- 通过一次操作,将这些更改应用于先前扫描的所有工件

- 评估经过重新测量的对象的质量,并根据需要调整参数

通过分析之前装配的工件快速调查失效原因

- 向失效工件添加新测量对象,以获得更多信息

- 创建专门用于调查的新控制和报告

- 通过一次操作,向选定工件的子集中添加新对象和报告

- 分析新尺寸控制的统计数据和趋势图

InnovMetric, the independent software development company that empowers manufacturers of every size to digitally transform their 3D measurement processes, has launched PolyWorks 2022, the latest release of its smart 3D metrology digital ecosystem.

PolyWorks 2022 offers new key functionalities that significantly expand the capabilities of its three ecosystem foundations:

– The universal 3D metrology platform now facilitates multipiece inspection when CAD data is not available as well as introduces a universal data hub

– Digital connectivity between data and people is improved by enabling the deployment of global metadata management strategies and the programming of alerts that automatically detect failing dimensions and notify the right people in real time

– The collaboration between probing operators and their measurement hardware is raised to a new level by mixed reality display technology that enhances the operators’ perception of 3D metrology

PolyWorks 2022 also demonstrates InnovMetric’s commitment towards open solutions by releasing an API to query data from its data management solution and inject it into third-party software applications.

Universal platform extensions

Manufacturing organizations often need to measure and inspect multiple pieces even though they do not have access to a reliable 3D CAD representation of those pieces. For example, in the early stages of a product engineering cycle or after having physically adjusted the design on the shop floor. To address these measurement scenarios, the PolyWorks universal platform offers a new feature measurement guide technology to guide probing, scanning, and feature extraction when measuring and inspecting multiple pieces in the absence of CAD data and nominal feature components. Users can inject a CAD model and nominal feature components at any point later in the process and propagate these changes to already-measured pieces.

The PolyWorks universal platform also features a new universal data hub that brings all relevant data under one roof:

– Inspection projects can be created automatically from third-party software measurement results and shared digitally enterprisewide

– Native CAD and QIF MBD file readers import all GD&T control types to ensure digital interoperability with the product definition processes

– Users can also use a more accurate device to measure a dimensional control and inject the measured value within a scanned or probed object for reporting purposes

Improved digital connectivity for consumers of 3D measurement data

In a 3D metrology context, metadata consists of important attributes describing the part design, piece fabrication, and 3D measurement processes. PolyWorks 2022 ensures metadata is meaningful and usable by managing shared properties common to multiple inspection projects and piece templates. Unified and synchronized shared properties empower searches, filtering, and analysis across the broad centralized 3D metrology data archive.

PolyWorks 2022 also enables production teams to program alerts that monitor incoming measurements and notify the right people by e-mail when a dimension is out of tolerance or out of control. Notifications enable real-time reactivity as they include a hyperlink that instantaneously opens the problematic piece within a Web-based 3D viewer. From there, users can quickly assemble an investigation team using the PolyWorks modern digital communication technologies.

More efficient probing workflows through mixed reality display

Mixed-reality display technology enhances the perception of 3D metrology by superimposing holograms on inspected pieces and offering an instinctual gesture-based user interface. The PolyWorks 2022 mixed-reality solution provides new visual guidance and feedback capabilities that optimize the efficiency of probing operators. In addition to overlaying guidance geometry and measurement instructions on the inspected piece, it also displays probed points, measurement results, and the digital readout in real time, and allows users to invoke common probing functionalities remotely.

Open solution

Manufacturing organizations need open solutions to interconnect their multiple enterprise solutions digitally and optimize their efficiency. InnovMetric is proud to announce the availability of an API for its data management solution. Based on the OData open protocol, the PolyWorks 2022 secure REST API allows third-party software applications to access the hierarchy of workspaces, projects, and pieces, and the measurement objects and controls of individual pieces. The PolyWorks REST API is compatible with data analysis solutions, such as Tableau, PowerBI, and Excel, and allows users to inject parametric URLs referring to measured pieces into other enterprise solutions, such as PLM, ERP, or MES solutions, and to transfer information to other digital systems using programming languages, such as Python and C#.

PolyWorks is the leading software solution for high-end point cloud inspection and reverse engineering applications. Defining the cutting edge of 3D metrology, the software suite maximizes productivity, quality, and profitability when integrating 3D measurement technologies into an industrial manufacturing process.

From part and tool design and prototyping down to final inspection of assembled products, PolyWorks software offers advanced solutions to cover the complete product development cycle. Interfacing directly with major brands and technologies of single-point and point cloud 3D measurement devices through plug-in extension modules, this universal platform also supports a wide array of native point cloud and polygonal model file formats. With its fully customizable user interface and powerful, user-friendly macro programming language, PolyWorks offers the most adaptable software solution on the 3D metrology market. This flexibility allows our customers to successfully develop and deploy automatic inspection processes or guided operator-driven workflows for effective shop floor operations.

This is a quick demo on how to create features using a CAD model. PolyWorks is really powerful when it comes to comparing a CAD file to a 3D scan, it is very easy to define features to be measured automatically.

InnovMetric is an independent software development company that empowers manufacturers of every size to digitally transform their 3D measurement processes. InnovMetric revolutionized 3D metrology with the introduction of point-cloud-based dimensional inspection in 2000 and the concept of a universal 3D metrology software platform in 2006. Today, with over 17,000 customers in 98 countries, and the world’s largest industrial manufacturers having adopted its PolyWorks solutions as their standard 3D metrology software platform, InnovMetric is focusing on creating next-generation digital data and process management technologies. Headquartered in Quebec City, Canada, InnovMetric is a multinational organization with 500 employees dedicated to bringing 3D measurement data at the heart of enterprise manufacturing processes.

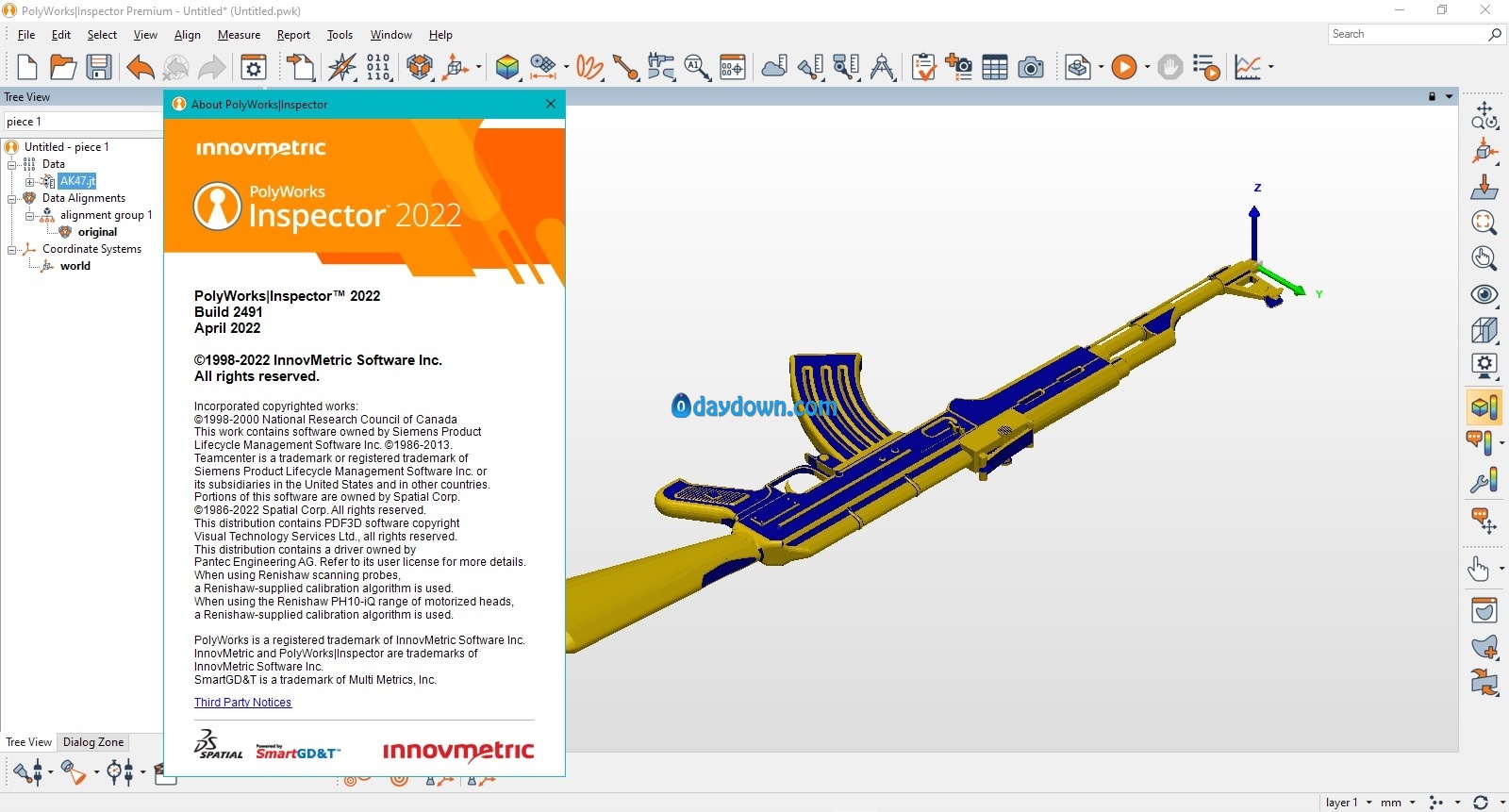

Product: InnovMetric PolyWorks Metrology Suite

Version: 2022 IR0 Build 2491

Supported Architectures: x64

Website Home Page : http://www.innovmetric.com

Languages Supported: english

System Requirements: Windows *

Size: 1.7 Gb

Password/解压密码www.tbtos.com