MSC Nastran的是世界上使用最广泛的有限元分析(FEA)求解器。当涉及到模拟压力,动力,还是现实世界的震动以及复杂的系统时,MSC Nastran仍然是目前世界上最好的和最值得信赖的软件。今天,有限元求解器是可靠和准确的,足以通过FAA和其他监管机构的认证,所以零件到复杂装配的制造商都选择了有限元求解器。

负责仿真原型制造的工程师和分析师面临着巨大的挑战,他们需要尽可能快的产生结果,从而能够影响决策制定,并且结果要足够准确,从而能够让他们的公司和管理者有信心用仿真取代物理样机。在当今世界,没有人有时间或预算花费在评价其有限元分析软件的准确性上,所以必须知道它是正确的。

MSC Nastran是建立在由美国国家航空和航天管理局的科学家和研究人员所做的工作基础上的,是值得信赖的设计,并且用在每个行业的关键任务系统。几乎每一个航天器,飞机,以及在过去40年来设计的车辆都通过使用MSC Nastran进行了分析。近年来,我们已经将了CAE最优秀的科学家投入到MSC Nastran中,以扩大其力量和效率,从而确保了它能够在目前持续维持世界最好的,最值得信赖的,最广泛使用的有限元软件的地位。新的模块化打包让您只得到您需要的部分,这使得您比以往拥有Nastran所花费的费用要少。

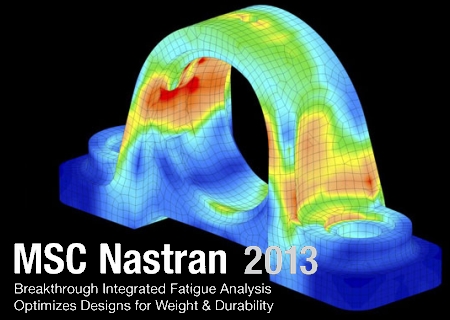

MSC Nastran 2013.1 | 2.4 Gb

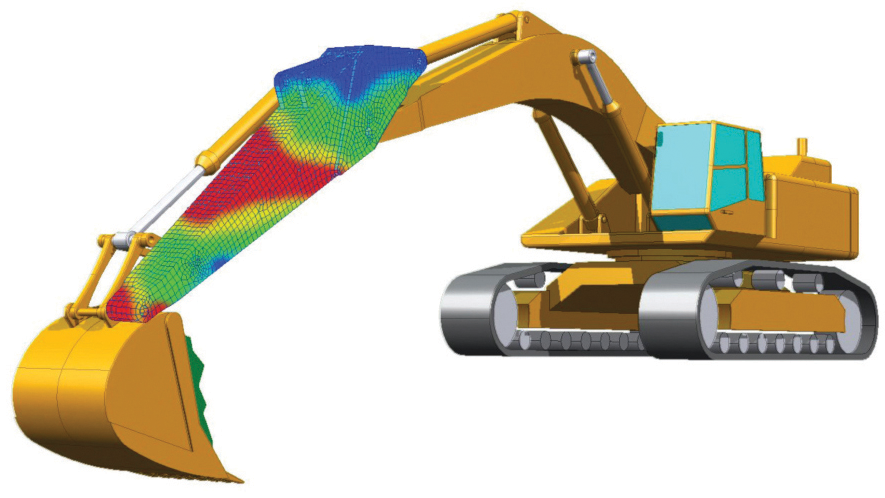

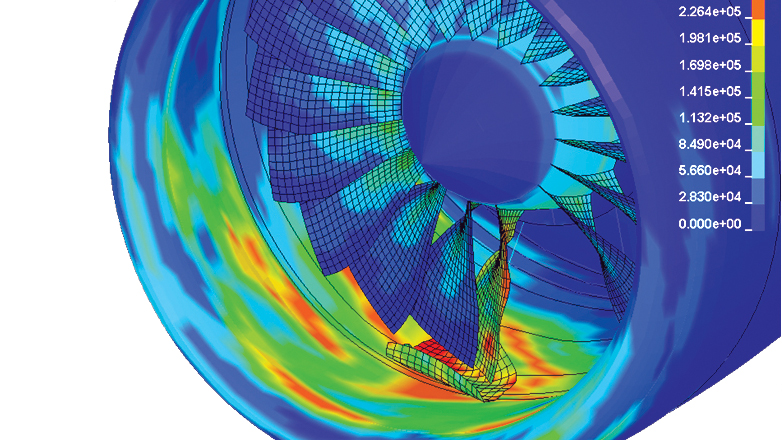

MSC Software Corporation, the leader in multidiscipline simulation solutions that accelerate product innovation, announced the new release of MSC Nastran 2013. The new features of MSC Nastran 2013 deliver customization and broader solution capabilities that generate significant time savings in automotive and aerospace simulation workflows.

Embedded Fatigue Analysis

The new release integrates industry leading fatigue analysis capabilities within MSC Nastran. Engineers can now calculate fatigue damage and life using the MSC Nastran solver without the need to export results to a separate fatigue solution. What was once a post-processing exercise is now an integral part of the analysis process, providing multiple advantages, one of which is the ability to do weight optimization while constraining fatigue life.

– Significant time savings are achieved by avoiding sequential process steps in the durability calculations. This reduces both computational time (in one scenario, a fatigue analysis that traditionally took 8 hours, took just 38 minutes) and dramatically improves ease of use (200 files to process is reduced to 2)

– Users can now perform design optimization in conjunction with fatigue analysis, which leads to better designs that last longer. One example led to a 24% mass reduction and at the same time fatigue life was increased by 14%

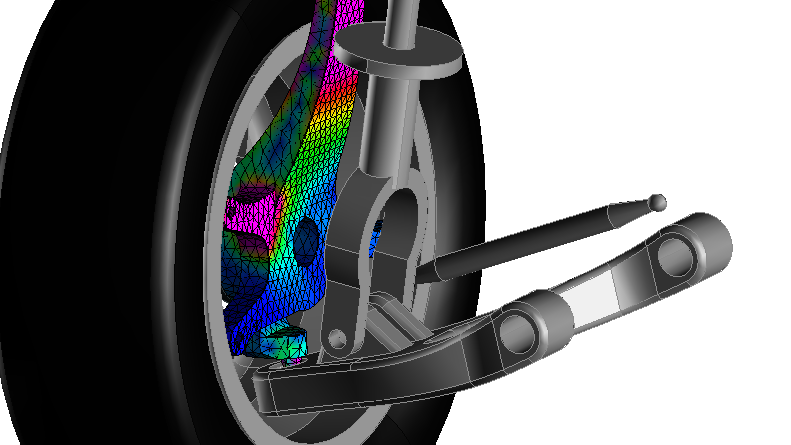

Poroelastic Material Modeling

Trim components are used extensively in automobiles and aircrafts to dampen the vibrations and improve the cabin comfort for the occupants. The new version supports the poroelastic behavior of these trim components to analyze the vibroacoustic performance of the vehicle by modeling the complex multi-physics of the fluid-solid interaction, resulting in improved simulation accuracy.

Advanced Nonlinear

The new release provides additional flexibility in model creation and functionality to improve accuracy of systems analysis.

– User defined material subroutine has been improved enabling engineers to define new state variables and with ability to pass additional internal variables

– Enforced relative motion capability is improved for better nonlinear dynamic analysis of structures

– MNF files that are used by Adams to simulate deformation in flexible bodies can now be exported at a deformed configuration as well

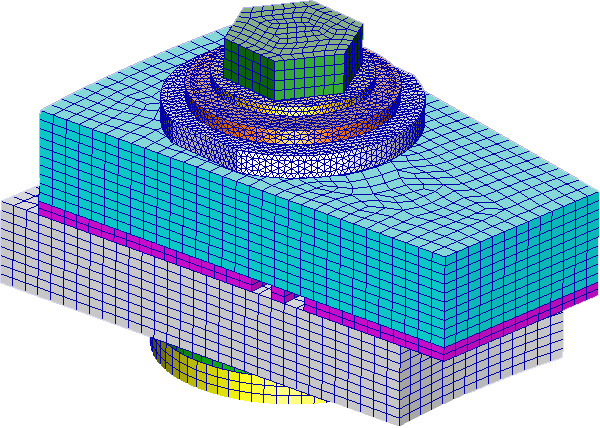

Explicit Nonlinear

Several new capabilities to improve the performance of the numerically intensive blast and general fluid-structure interaction (FSI) applications have been implemented in this release. They include:

– New 1D to 3D and 2D to 3D axisymmetric mapping for blast loads in Eulerian solver. With this capability, users can improve the computational speed of these analyses by performing one- or two-dimensional analyses and mapping the results to a three dimensional mesh when needed to account for effect of the wave on a structure.

– Multiple detonation points with varying ignition times for blast applications to analyze multiple blasts and their effects on structural integrity

– New methodology to define blast loads based on empirical data in LS-Dyna

– New LS-Dyna libraries based on LS-Dyna version MPP 971s R6.0.0

– Enhancements to FSI algorithms to speed up the simulation time, with over 60% improvement seen in single core runs and even better performance for multicore runs.

High Performance Computing

With solver enhancements and parallelization capabilities, MSC Nastran delivers performance improvements for a variety of analyses. Greater use of parallelization and GPGPU technology results in 20%-50% reduction in solution times over previous release, providing an opportunity to simulate more designs.

– Improved support for GPU devices for higher productivity

– DMP (Distributed Memory Parallel) capabilities for advanced nonlinear analysis capabilities made more efficient (57% reduction in analysis time was achieved for a customer model)

– New memory management to minimize memory use in order to conserve resources in a multi-user environment

About MSC Software

MSC Software is one of the ten original software companies and the worldwide leader in multidiscipline simulation. As a trusted partner, MSC Software helps companies improve quality, save time, and reduce costs associated with design and test of manufactured products. Academic institutions, researchers, and students employ MSC’s technology to expand individual knowledge as well as expand the horizon of simulation. MSC Software employs 1,100 professionals in 20 countries. For additional information about MSC Software’s products and services, please visit: http://www.mscsoftware.com

The MSC Software corporate logo, Simulating Reality, MSC Nastran, Adams, Actran, Digimat, Dytran, Easy5, Marc, Patran, MSC, MasterKey, MasterKey Plus, Mvision, SimDesigner, SimManager, and SimXpert are trademarks or registered trademarks of MSC Software Corporation and/or its subsidiaries in the United States and/or other countries. NASTRAN is a registered trademark of NASA. All other trademarks belong to their respective owners.

Name: MSC Nastran

Version: 2013.1

Home: www.mscsoftware.com

Interface: english

OS: Windows XP / Vista / Seven / 8

Size: 2.4 Gb

MSC Nastran 2013.1.1

Download rapidgator

http://rg.to/file/29fe3b9527d466e24565c1b4c93d8bd4/m-mn1311.part1.rar.html

http://rg.to/file/ab241be3c44c591c53ecb69013ad8ed7/m-mn1311.part2.rar.html

http://rg.to/file/12154132fb2a7a584333f2480044e6f2/m-mn1311.part3.rar.html

http://rg.to/file/452df38a5678cb1bc6c273ded3e94f35/m-mn1311.part4.rar.html

Download uploaded

http://uploaded.net/file/sxlj1dfo/m-mn1311.part1.rar

http://uploaded.net/file/u6lhuvse/m-mn1311.part2.rar

http://uploaded.net/file/meood78w/m-mn1311.part3.rar

http://uploaded.net/file/upqkhers/m-mn1311.part4.rar

Download Firedrive and 百度云

你是VIP 1个月(1 month)赞助会员,

转载请注明:0daytown » MSC Nastran 2013.1.1

与本文相关的文章

- Compost 14.0.16.0 x64

- Siemens NX 2206 Build 9220 (NX 2206 Series)

- Siemens Simcenter Amesim 2404 x64

- InventorCAM 2023 SP3 for Autodesk Inventor 2018-2024 x64 Multilingual

- Siemens NX 2306 Build 8900 (NX 2306 Series)

- GibbsCAM 2024 v24.0.64.0 x64

- AVL Workspace 2024 R1 x64

- AVL Simulation Suite 2024 R1 x64

- Tekla Structures 2024 SP2 x64 Multilingual

- FunctionBay RecurDyn 2024 SP1 x64 Multilingual

- Compost 14.0.16.0 x64

- Altium Designer 24.5.1 x64