钣金成形模拟解决方案

概述

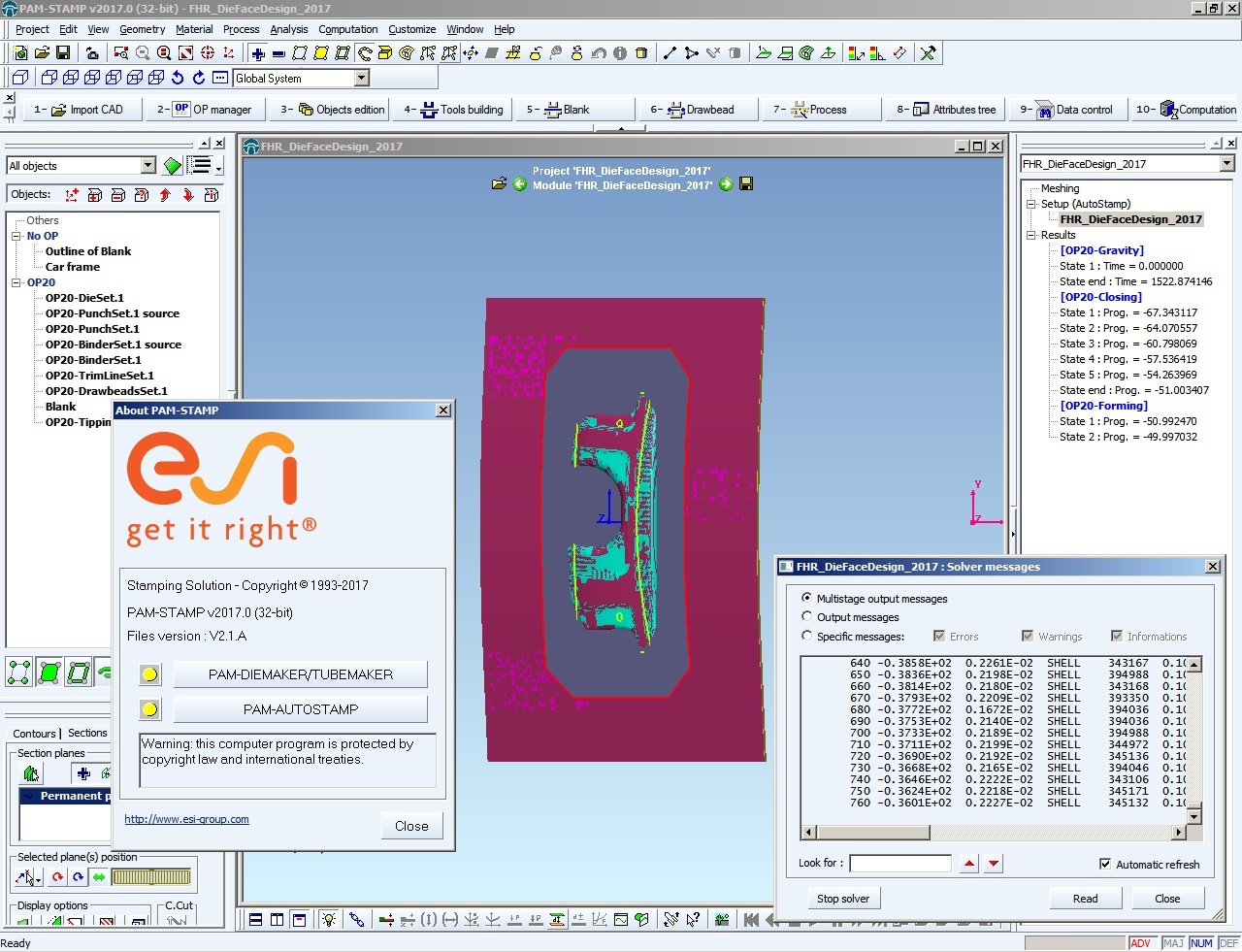

PAM-STAMP 2G是完善的,集成的,可扩展和流程式的成形模拟解决方案。覆盖从模具论证到模具设计、可成形性模拟和试验验证模拟的完整加工过程。

PAM-STAMP 2G提供了一个产品设计师、原料提供商、模具设计师和模具试模人员等进行产品联合开发的钣金成形模拟集成平台,结果通过各种方法如图像、动画、文本和三维数据模型等输出,模拟结果报告在整个产品开发团队中共享,用户可以根据模拟结果不断改进产品设计生产过程,为用户创造最好的产品提供可靠依据。

特点和规格

满足当前工业需求

通过与工业合作伙伴的联合开发,ESI集团开发的PAM-STAMP 2G钣金成形模拟解决方案完全响应客户的实际需求,包括OEM合作伙伴、原料提供商、工具制造商等。

在软件的各模块中,材料数据库和数据模型能实现无缝共享,用户所关心的只是实际的成形过程,而无需在软件使用中分散精力。

产品集成

通过和领先的计算机硬件厂商合作,ESI集团开发了智能化仿真技术完美地把计算机软件和硬件结合起来,提供给用户最好的钣金成形模拟解决方案。

通过使用新的软件用户浮动许可证系统,用户可以同时使用PAM-STAMP 2G 的所有模块,包括PAM-DIEMAKER, PAM-QUIKSTAMP, PAM-AUTOSTAMP and the Stamping Professional Pack。

PLM协同开发的最佳工具

PAM-STAMP 2G提供了独一无二的所有钣金成形过程模拟价值链集成解决方案,解决从快速模具设计,到早期可行性,最终验证和质量控制,而没有发生模拟的中断。

提升产品生命周期管理(PLM),带给设计师和试制专家在协同环境中在线决策。

成形可行性验证循环

成形可行性验证循环是在PAM-DIEMAKER和PAM-QUIKSTAMP间轻松实现设计的迭代循环,得到成形快速模拟结果,完成模具设计可行性评估功能。

成形精确验证循环

成形精确验证循环是在PAM-DIEMAKER和PAM-AUTOSTAMP间轻松实现设计的迭代循环,得到成形精确模拟结果,完成模具设计质量控制功能。

The release of ESI PAM-STAMP 2017 delivers major efficiency improvements for setting up progressive, transfer and line dies. ESI engineers have redesigned the User Interface (UI) in order to significantly reduce the number of “clicks” and drastically increase work efficiency. Setting up processes is now done directly following a new and streamlined horizontal workflow, facilitating the setup of the entire stamping process; end to end.

ESI Group is a leading innovator in Virtual Prototyping software and services. Specialist in material physics, ESI has developed a unique proficiency in helping industrial manufacturers replace physical prototypes by virtually replicating the fabrication, assembly and testing of products in different environments. Today, coupled with Virtual Reality, animated by systems models, and benefiting from data analytics, Virtual Prototyping becomes immersive and interactive: ESI’s clients can bring their products to life, ensuring reliable performance, serviceability and maintainability. ESI solutions help world-leading OEM’s and innovative companies make sure that their products will pass certification tests – before any physical prototype is built – and that new products are competitive in their market space. Virtual Prototyping addresses the emerging need for products to be smart and autonomous and supports industrial manufacturers in their digital transformation.

For any given metal forming process, it is possible today to conceive everything in a virtual engineering equivalent – from detailing customer requests to virtually inspecting the final product, as well as setting-up the production facilities. This includes material cost estimation, die design and feasibility, part design validation and tooling design and forming processes.

Making engineers productive – What is available and how does it work:

– Topology check, cleanup and repair

– Material cost estimation

– Die face design next generation based on B-Spline geometry

– Fast link with simulation

– Accurate numerical methods

– Geometrical drawbeads

– Springback – Kinematic Hardening Model

– Ironing

– Triple speed mode for breathtaking short simulation times

– Precise prediction of wrinkles including folding – no numerical flattening

– Blank & Trim Line Optimization

– Springback of High Strength Steel

– (Multi-operation) compensation

– Virtual prototyping of the full stamping chain

– Cosmetic defects

– Customization

– High quality results without tradeoffs in cost and time

– Hot Forming , End-to-End Virtual Prototyping

– Chaining with manufacturing engineering and assembly prototyping

– Virtual Reality

ESI.PAM-Stamp.2017.0.Win-SSQ

Home Page – https://www.esi-group.com/

Download uploaded

http://uploaded.net/file/scerj3kx/ESI.PAM-Stamp.2017.0.Win-SSQ.rar

Download nitroflare

http://nitroflare.com/view/4F2BB08EC718313/ESI.PAM-Stamp.2017.0.Win-SSQ.rar

Download 百度云

你是VIP 1个月(1 month)赞助会员,